- +86 519 83258428

- market@baosteelroll.com.cn

- 41, Xinye Road, Changzhou, Jiangsu, China

BYR8 WR is a forged steel semi-high-speed roll for non-ferrous hot rolling, which is developed by optimizing the alloy content of Si, Mo, V, etc. on the basis of Cr5. The roll has high hardness, high tempering temperature, and high fatigue resistance characteristics, which benefits from the combination with a reasonable heat treatment process.

properties and characteristics

BYR8 WR is a forged steel semi-high-speed roll for non-ferrous hot rolling, which is developed by optimizing the alloy content of Si, Mo, V, etc. on the basis of Cr5. The roll has high hardness, high tempering temperature, and high fatigue resistance characteristics, which benefits from the combination with a reasonable heat treatment process.

Smelting process : smelting + LF + VD + ESR

component desigh(Wt%):

| C | Si | Mn | Cr | Ni | Mo | V |

| 0.40

/1.00 |

0.70

/1.30 |

0.10

/0.70 |

3.50

/7.50 |

0.20

/1.00 |

0.80

/1.50 |

0.20

/0.80 |

Table 1 component range of BYR8

Main technical parameters:

Hardness: ≥ 80HSD

Tempering temperature: ≥500 ℃

Hardening depth: ≥ 50mm

Neck strength Rm: ≥ 1000Mpa

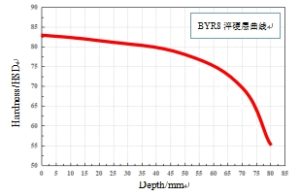

Hardening depth curve:

Maintenance:

The property of roll depends on its quality and scientific rationality of maintenance method. The maintenance of BYR8 is similar to normal rolls, which can be executed according to Table 2 below.

| material | Recommended grinding wheel | Recommended grinding feed | Detection method |

| BYR8 | SA/DA、60/80#、J/K | single≤5um | SUT |

Table 2 maintenance advice of BYR8

Recommended using scope:

BYR8 is recommended for non-ferrous rough rolling and hot finish rolling, especially for non-ferrous hot rolling lines with high hardness requirement.

Main customers:

Baosteel Roll Science & Technology Co.,Ltd