- +86 519 83258428

- market@baosteelroll.com.cn

- 41, Xinye Road, Changzhou, Jiangsu, China

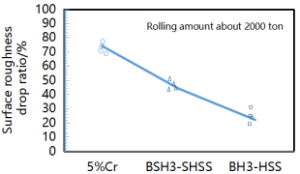

BH3 forged steel roll changes traditional,heat treatment processes and increases the content of elements such as C, Mo, and V,in order to obtain high hardness carbides such as MC, M2C, and M7C3, achieving high wear resistance, high roughness retention, and easy grinding performance

BH3 forged high-speed steel work roll for cold rolling

Some details about forged steel rollers: materials and production

•Material: Usually made of high-strength materials such as high-carbon steel and alloy steel.

•Manufacturing process: including forging, heat treatment, machining and other steps. Among them, forging is a key step, which can significantly improve the density and mechanical properties of the material.

Features

•High strength and hardness: able to withstand heavy loads and suitable for high temperature and high pressure working environments.

•Wear resistance: After special treatment, the surface has good wear resistance and extends its service life.

•Good fatigue resistance: stable performance even under long-term operation.

•Precise dimensional control: Through precision processing technology, the dimensional accuracy of forged steel rollers is ensured to meet the needs of different application scenarios.

BH3 forged steel roll changes traditional,heat treatment processes and increases the content of elements such as C, Mo, and V,in order to obtain high hardness carbides such as MC, M2C, and M7C3, achieving high wear resistance, high roughness retention, and easy grinding performance.

Smelting process: smelting + LF + ESR

Properties and characteristics:

Component design:

Table 1 component range of BH3

| C | Si | Mn | Cr | Mo | V | Ni |

| 0.80

/1.20 |

0.60

/1.50 |

0.40

/1.50 |

450

/7.00 |

1.20

/2.50 |

0.80

/1.50 |

0.40

/1.00 |

Main technical parameters:

| Hardness:≥ 88HSD(62HRC) |

| Residual stress: ≤ -300Mpa |

| Residual austenite content:≤ 8% |

| Neck strength Rm:≥ 900MPa |

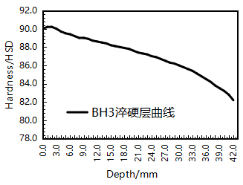

curve of hardening depth

Performance:

Maintenance:

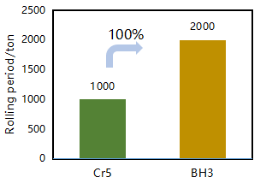

The property of roll depends on its quality and scientific rationality of maintenance method. The maintenance of BH3 is similar to normal Cr5 rolls and semi-high speed steel roll, which can be executed according to Table 2 below.

Table 2 maintenance of BH3 comparing with Cr5

| Material | Roll change period | Grinding efficiency | Grinding feed | Recommended grinding wheel | Ra range | Detection |

| Cr5 | A | 1 | ≥

0.2mm |

SA/DA、60/80#,

resin/ceramics、J/K |

0.3

-1.2 |

SUT |

| BH3 | 1.5A

-3.0A |

1.2 | ≥

0.2mm |

5SG46/80(G/EF)

Ceramic grinding wheel |

0.3

-1.2 |

SUT |

Recommended using scope:

Recommended for production lines with high accidents rates or high roughness requirements, such as silicon steel, high-strength steel and automotive sheets, in order to improve anti-accidents ability and increase roll changing periods.The stand F1-F4 is recommended.

Main customers:

![]()

Baosteel Roll Science & Technology Co.,Ltd